Elevate Your Workshop: Discover the Perfect Machine Vise

Introduction to Machine Vises

In every craftsman's workshop, precision and safety are paramount. A machine vise, an essential tool for machinists and hobbyists alike, ensures that workpieces are held securely, allowing for accurate machining operations. Whether you are drilling, milling, or grinding, understanding the importance of a quality machine vise can significantly impact your work's outcome.

Understanding Machine Vises: Types and Uses

Machine vises come in various forms, each designed for specific tasks and machinery. From bench vises to precision milling vises, selecting the right type can make all the difference in your projects.

Bench Vises: A Workshop Staple

Discover the versatility of bench vises and why they are a must-have in any workshop. Their robust design and ease of use make them ideal for a wide range of applications.

Precision Milling Vises: Enhancing Accuracy

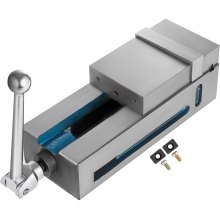

Delve into the world of precision milling vises, designed for high-accuracy machining. Learn how these vises can enhance your milling operations and improve your work's overall precision.

Drill Press Vises: Secure and Steady

Explore the features of drill press vises, specifically designed to hold workpieces steady during drilling operations. Understand how they contribute to safer and more precise drilling.

Hydraulic and Pneumatic Vises: Advanced Clamping Solutions

Uncover the benefits of hydraulic and pneumatic vises for high-volume or heavy-duty machining. Their automated clamping mechanisms can significantly reduce setup time and increase efficiency.

Selecting the Right Machine Vise for Your Workshop

Choosing the correct machine vise is crucial for the success of your machining operations. This section guides you through the factors to consider when selecting a vise, such as material, size, and clamping force.

Material Matters: Cast Iron vs. Steel

Examine the pros and cons of different vise materials, from traditional cast iron to modern steel alloys, and determine which is best suited for your specific needs.

Size and Capacity: Matching Your Machine

Learn how to match the size and capacity of a machine vise to your machinery and workpieces. A correctly sized vise ensures optimal performance and safety.

Clamping Force: Finding the Balance

Understand the importance of clamping force in machining operations and how to select a vise that provides sufficient pressure without damaging your workpieces.

Installation and Maintenance: Ensuring Longevity and Precision

Proper installation and maintenance are essential for the longevity and performance of your machine vise. This section provides step-by-step instructions on setting up your vise and keeping it in top condition.

Setting Up Your Machine Vise

Follow our detailed guide to properly install your machine vise, ensuring it is aligned and secure for accurate machining.

Routine Maintenance Tips

Discover essential maintenance tips to keep your machine vise operating smoothly. Regular cleaning and lubrication can prevent wear and extend your vise's life.

Safety First: Operating Your Machine Vise

Safety should always be a priority in any workshop. This section covers the dos and don'ts of operating a machine vise, ensuring you work safely and efficiently.

Proper Workpiece Clamping

Learn the correct way to clamp workpieces in your machine vise to prevent slippage and accidents during machining operations.

Avoiding Common Mistakes

Be aware of common mistakes and how to avoid them, ensuring your safety and the safety of your workpieces.

Creative Projects and Advanced Techniques

Once you've mastered the basics, explore creative projects and advanced techniques that can be achieved with a quality machine vise.

Innovative Uses for Your Machine Vise

Get inspired with ideas for innovative uses of your machine vise, from artistic endeavors to complex engineering projects.

Advanced Machining Techniques

Expand your skills with advanced machining techniques that leverage the capabilities of your machine vise, taking your projects to the next level.

Choosing the Right Brand: Why VEVOR Stands Out

When investing in a machine vise, choosing a brand that stands for quality and reliability is essential. Discover why VEVOR is the preferred choice for professionals and hobbyists alike.

VEVOR's Commitment to Quality

Learn about VEVOR's commitment to producing high-quality machine vises that meet the needs of even the most demanding users.

A Range of Options to Suit Every Need

Explore VEVOR's extensive range of machine vises, designed to suit every need and budget. Find the perfect vise for your workshop and projects.

Conclusion: Elevating Your Machining with the Right Vise

A quality machine vise is an investment in your workshop's future, enhancing the precision, safety, and efficiency of your machining operations. As you've learned, selecting, maintaining, and safely using the right vise can significantly impact your work's quality.

Take the Next Step with VEVOR

Ready to elevate your machining projects? Explore VEVOR's range of high-quality machine vises today and find the perfect fit for your workshop needs. Whether you’re a seasoned professional or just starting out, VEVOR offers a variety of vises to meet your specific requirements and budget.

Customer Support and Satisfaction

VEVOR prides itself on excellent customer support and satisfaction. Should you have any questions or need assistance choosing the right machine vise, our team is here to help. We ensure you get the most out of your purchase with advice, tips, and comprehensive after-sales service.

Invest in Quality, Invest in Efficiency

Investing in a high-quality machine vise is investing in your work's future. With the right tools, you can achieve greater precision, efficiency, and safety. Remember, a good vise not only holds your workpiece; it holds the key to better results.

Final Thoughts: Your Workshop's Essential Companion

As we conclude this guide, remember that a machine vise is more than just a tool; it’s an essential companion in your workshop that contributes significantly to the success of your projects. By choosing the right vise, maintaining it properly, and adhering to safety practices, you can ensure a productive and successful machining experience.

Ready to Transform Your Machining Process?

Don’t wait any longer to enhance your workshop capabilities. Explore VEVOR’s selection today and discover the perfect machine vise that will transform your machining process, enhance your productivity, and help you achieve the high-quality results you aspire to.

Remember, with VEVOR, you’re not just buying a tool; you’re investing in a partnership that values quality, reliability, and customer satisfaction. Join the multitude of satisfied customers and experience the VEVOR difference in your machining endeavors.

FAQs about Machine Vise

What Is a Machine Vise and What Is It Used For?

A machine vise is a mechanical device used to secure an object to allow work to be performed on it. Machine vises are typically used in metalworking, though they can also be found in the woodworking and plastic working industries. They are crucial for tasks that require precision, such as drilling, milling, and grinding, as they hold the workpiece steady, ensuring accuracy and safety during operations.

How Do I Choose the Right Machine Vise for My Needs?

Selecting the right machine vise depends on several factors: the type of work you're doing, the size and weight of the materials you're working with, and the specific features you might need. Consider the material of the vise, typically cast iron or steel, for durability and longevity. Look at the size to ensure it fits your workbench and accommodates your workpieces. Additionally, assess the vise's clamping force and whether it provides sufficient pressure without damaging your materials. It's also wise to check for additional features like jaw width, opening capacity, and whether it rotates or has a fixed base.

How Do I Maintain My Machine Vise to Ensure Longevity?

Maintaining your machine vise involves regular cleaning, lubrication, and inspection. Remove any debris, chips, or dust from the vise after each use to prevent buildup. Apply lubricant to moving parts to ensure smooth operation and protect against rust. Periodically check for wear and tear, especially on the jaws and screw mechanism. If any parts are worn out or damaged, replace them immediately to maintain the vise’s performance and safety.

Can I Use a Machine Vise with Different Types of Machines?

Yes, machine vises are versatile and can be used with various machines, including milling machines, drill presses, and grinders. However, ensure that the vise you choose is compatible with the specific type of machine you intend to use it with. For example, a precision milling vise is best suited for milling operations due to its accuracy, while a drill press vise is optimized for holding objects securely during drilling.

What Safety Precautions Should I Take When Using a Machine Vise?

Safety is paramount when using a machine vise. Always secure the vise properly to your workbench or machine table to prevent it from moving during operations. Ensure that the workpiece is clamped tightly within the vise to avoid slippage, which can lead to accidents or damage. Wear appropriate safety gear, such as gloves and eye protection, and keep your hands clear of the area where machining is taking place. Finally, always double-check that the vise and workpiece are securely fastened before starting any machine.